Manufacturer/Exporter Of High Quality Slip-On Forged Flanges

Carbon, Alloy, Stainless Steel Slip-On Flanges

Designed with an inside diameter slightly larger than that of the pipe being used, slip-on flanges are used for preventing leaks and providing strength. Although they tend to be more low cost than other types of flanges, a slip on flange allows less room for error when cutting a pipe. Because of the design of the slip on flange (also referred to as an SO flange), it is not necessary to have an exact cut on pipe length. PIPEFIT is a specialised manufacturer of high quality ASME/ANSI/DIN standard slip-on flanges in India. We offer immediate delivery programs for standard size of carbon steel slip-on flanges and stainless steel slip-on flanges. Slip-on flanges manufactured in special stainless steel grades, nickel alloy and alloy steel can be supplied with just in time programs.

We are indulged in crafting of slip on flanges which are precisely crafted with all expertise. These flanges are made using premium quality materials. This slip on pipe flanges are slipped over the pipe and then fillet welded.

ANSI B 16.5 Class 150

ANSI B 16.5 Class 300

ANSI B 16.5 Class 600

ANSI B 16.5 Class 900

ANSI B 16.5 Class 1500

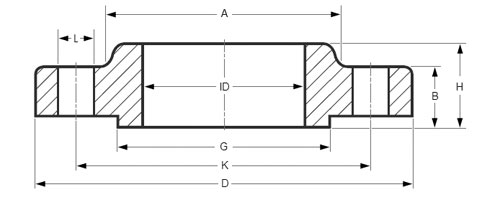

Dimensions Slip On Flanges & Stud Bolts ASME B16.5

| CL | 150 | 300 | 600 | 900 | 1500 | 2500 | ||||||||||||

| DIA A | 30 | 38 | 38 | 38 | 38 | ... | ||||||||||||

| DIA D | 90 | 95 | 95 | 120 | 120 | ... | ||||||||||||

| DIA B |

|

|

|

|

|

|

||||||||||||

| DIA G | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 | ... | ||||||||||||

| DIA K | 60.3 | 66.7 | 66.7 | 82.6 | 82.6 | ... | ||||||||||||

| H |

|

|

|

|

|

|

||||||||||||

| No L | 4 | 4 | 4 | 4 | 4 | ... | ||||||||||||

| DIA L | 15.9 | 15.9 | 15.9 | 22.2 | 22.2 | ... |

Stud Bolts Diameter x Length

| DIA (IN) | 1/2 | 1/2 | 1/2 | 3/4 | 3/4 | ... |

| Len mm | 55 | 65 | 75 | 110 | 110 | ... |

Other Diameters

| NPS |

|

|

|

|

|

|

|

Notes:

• Dimensions are in millimeters unless otherwise indicated.

• The length of the Stud Bolt does not include the height of the chamfers (points).

Slip-on Flange, SO Forged Flanges Production Range

Stainless Steel Slip-On (SO) Flange

Alloy Steel, Carbon Steel Slip-On (SO) Flange

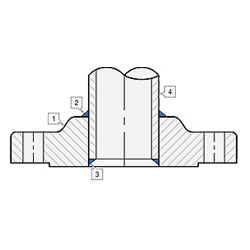

1-Slip On flange | 2-Filled weld outside | 3-Filled weld inside | 4-Pipe

Size: 1/2″ (15 NB) to 48″ (1200NB)

Standards: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Pressure Ratings: Class 150, Class 300, Class 400, Class 600, Class 900, Class1500, Class 2500 | PN6, PN10, PN16, PN25, PN40, PN64 etc.

Carbon Steel Slip-on Flanges: ASTM A105/A105N, A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, A694 F42, F46, F48, F50, F52, F56, F60, F65, F70, A516.60, 65, 70 (Spectacle Blind Flange, Spacer Ring/Spade Flange), Steel RST37.2, C22.8

Stainless Steel Slip-on Flanges: ASTM A182 F202, F304/304L/304H, F316/316L, F316H, F316TI, F310, F321, F904L

Alloy Steel Slip-on Flanges: ASTM A182 F1, F5, F9, F11, F22, F91

Special Alloy Slip-on Flanges: Duplex, Super Duplex, Nickel Alloys

Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Applying slip-on flanges

When applying an SO flange during a project, a connection with the pipe or tube is made with two fillet welds. Depending on the type of slip on flange, you may need to use both an outside weld, and an inside weld. Some slip on flanges require only and outside weld.